Pulverizer Rolls

When it comes to rebuilding pulverizer rolls, few can compete with RPM’s 35+ years of experience in which we have rebuilt over 2500 rolls. This knowledge and experience has been applied in the manufacture of RPM’s line of New Steel Core Pulverizer rolls. RPM stands out from the competition with our industry leading Tungsten Carbide wear band to enhance wear life and provide our customers with the lowest cost of ownership.

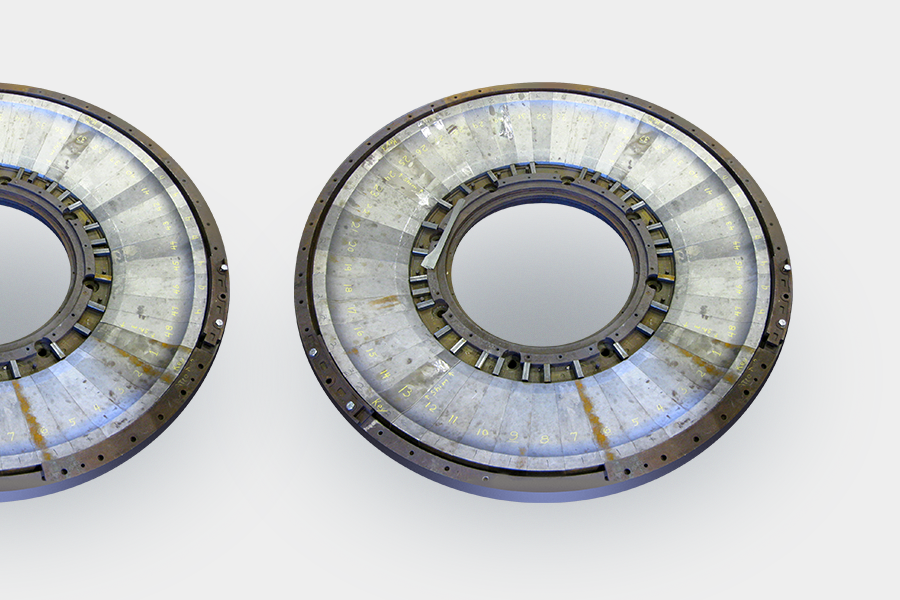

Pulverizer Tables

RPM has extensive experience overlaying pulverizer mill tables of many sizes and styles and rebuilds tables in-house or on-site depending on your needs. RPM also offers replacement New Steel Table Segments delivered with or without RPM’s engineered chrome carbide overlay.

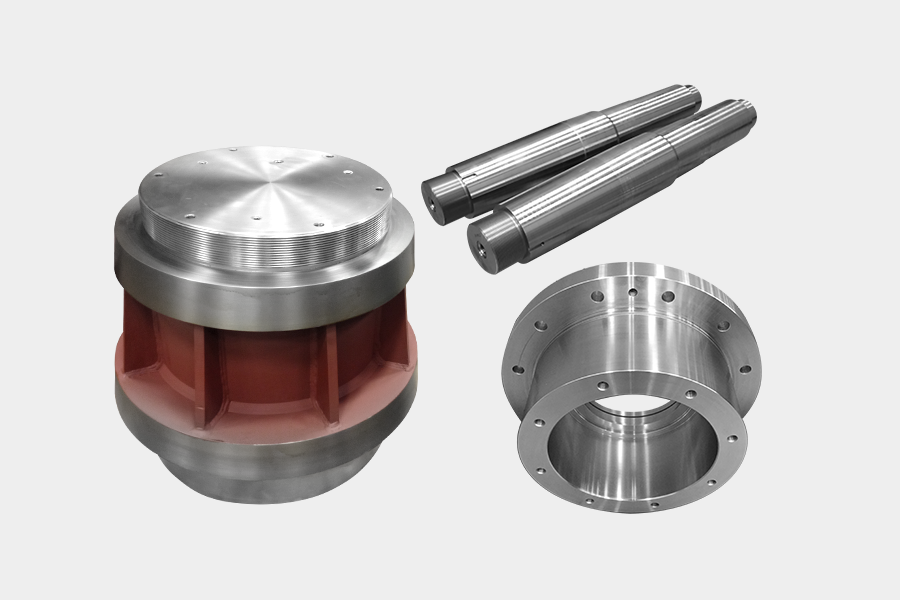

Journal Assembly Rebuilds

RPM journal rebuilds set a new standard of reliability, reduced maintenance, and lowest cost of ownership. RPM’s rebuild specifications meet or exceed OEM’s. RPM has the capabilities to repair, refurbish, manufacture new or supply journal components to achieve enhanced service life.

Journal Components

RPM has the capability to provide solutions for CE, MPS, MBF & HP style mills by manufacturing new or rebuilding worn components to upgrade or renew your coal mills. RPM rebuild services transform your worn or out-of-spec components into renewed parts that meet or exceed OEM specifications.

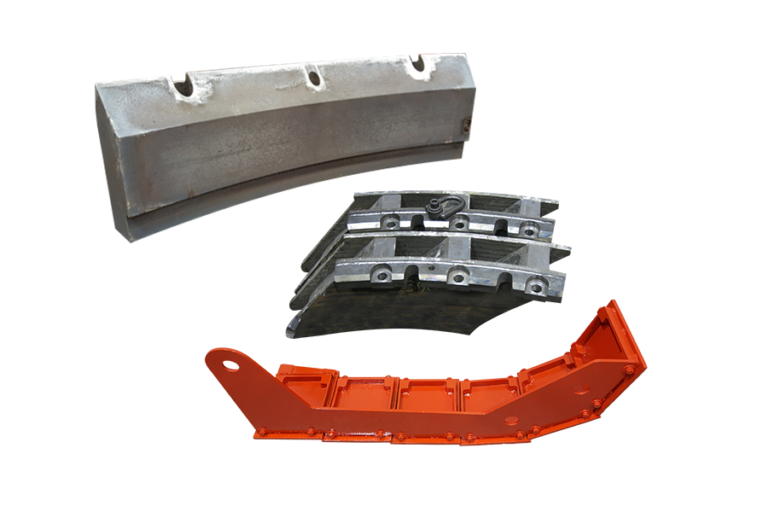

Mill Components

RPM manufactures engineered products for CE, MPS, MBF & HP style mills to upgrade and increase wear life on components in your existing coal mills. RPM solves problems!

Wear Liner Packages

RPM provides custom wear liner packages designed to solve your wear problem. Laser scanning equipment, coordinate measuring machines and CAD software are employed to provide an exact fit liner package. RPM uses creative material selection including RPM’s WEARx line of abrasion resistant products, tungsten carbide, creative geometries, and more… Like all RPM products, liner packages are designed to provide our customers with the lowest cost of ownership.

Wear Pipe

RPM’s Engineered Overlay is offered for multiple applications including: Fuel Piping, Bottom Ash Pipe, Coal Nozzles, Riffle Housings & other pipe-related parts used in high-abrasion/ erosion environments. RPM can Manufacture, Repair or Rebuild Smooth Radius Elbows, Flat Back Elbows, Tangents along with other fuel transport pipe.

Specialty Products

RPM provides custom solutions to your problem. Products include: Soot Blower Rollers, Gasifier Bearings, Kiln Burner Nozzles, Crane Wheels, Clutch Drums, Rotary Valves, Vertical Ball Mill Screws, Auxiliary Mill Drives and more.