RPM Composite Pulverizer Rolls

When it comes to rebuilding pulverizer rolls, few can compete with RPM’s 35+ years of experience in which we have rebuilt over 2500 rolls. This knowledge and experience has been applied in the manufacture of RPM’s line of New Steel Core Pulverizer rolls. RPM stands out from the competition with our industry leading Tungsten Carbide wear band to enhance wear life and provide our customers with the lowest cost of ownership.

RPM offers New Rolls for:

- CE/Alstom/GE/Raymond – RP/RS/RPS/HP & RB Style Rolls

- B&W Roll Wheel – MPS 89/89G & 98

- Foster Wheeler – MBF 22.5, 23 & 23.5

Advantages

RPM DIFFERENCE

- Pulverizer Parts Monitoring System – All parts new or rebuilt are ID’d and entered into the monitor system for traceability

- Cleaning Process performed by an automated parts washing machine

- Pre-weld Inspection Process – Visual Inspection, ID Crack Check, & Detailed Faro CMM Dimensional Inspection

- RPM’s engineered overlay applied using precise parameters and controlled environment

- Post-weld Inspection Process – Repeat pre-weld inspection with the addition of OD/ID concentricity inspection, ID surface finish documented, and final machining of ID bore if required

- All Quality Control performed by senior staff

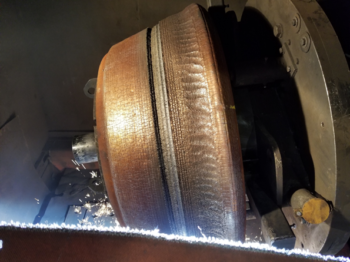

Pulverizer Roll Rebuilding

With over 35+ years of experience, RPM is the industry leader in rebuilding coal pulverizer rolls. RPM offers a variety of chrome carbide overlay options that are engineered to your application and specific to design of mill. RPM has the knowledge and capabilities to rebuild many styles and sizes of pulverizer rolls or wheels.

Typical Rolls or Wheels Rebuilt Include:

- CE/Alstom/GE/Raymond – RP/RS/RPS/HP & RB Style Rolls

- B&W Roll Wheel – MPS 89/89G & 98

- Foster Wheeler – MBF 22.5, 23 & 23.5

RPM Difference

RPM performs exact same quality process for all rebuilt rolls as new manufactured rolls.

CASE STUDY

CE 1003 Pulverizer Roll

Application: Coal Pulverizer Mill

Wear Item: Grinding Roll

Purpose: Conditions raw coal into fuel

Type of Wear: Severe Abrasion / Moderate Impact

Solution: RPM Engineered Chrome Carbide Overlay w/ Industry Leading Tungsten Carbide Wear Band

Benefits: Increased Wear Life, Reduce Chromium Output & Increased Mill Performance

MPS 89 Pulverizer Roll

Application: Coal Pulverizer Mill

Wear Item: Grinding Roll

Purpose: Conditions raw coal into fuel

Type of Wear: Severe Abrasion / Moderate Impact

Solution: RPM Engineered Chrome Carbide Overlay over new OEM High Chrome Roll

Benefits: Increased Wear Life, Low initial cost & extended maintenance cycles.