Who We Are

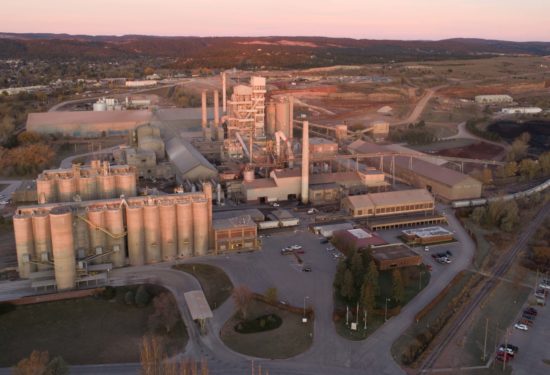

RPM & Associates, Inc has focused on providing innovative solutions for our industrial customers for 39+ years. We specialize in:

Hardfacing Solutions of Wear Related Components

Manufacture of WEARx Premium Plate Products

Design & Engineering Solutions

Specialty Manufacturing

Heavy Mechanical Services

Pulverizer Mill Components

On-Site Services

Community Involvement

Featured Products

New RPM Pulverizer roll

- Focused on Lowest Cost of Ownership

- New rolls manufactured from Steel Cores are a Lifetime Investment

- Fully Rebuildable

- Steel Core Resistant to Cracking or Breaking

- RPM Engineered Wear Profile Based off 30+ Years of

recorded inspections - RPM Engineered Premium Chrome Carbide Overlay

- Industry Leading Tungsten Carbide Chip Wear Band

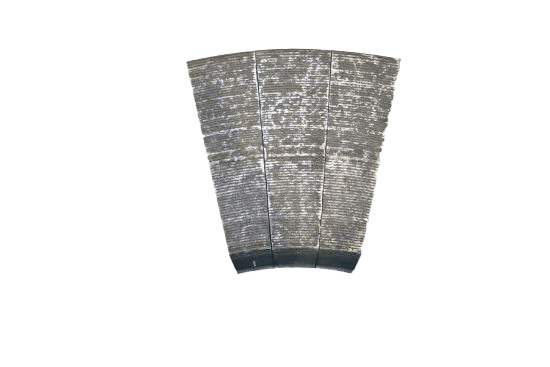

New RPM Steel Table Segments

- Focused on Lowest Cost of Ownership

- New Segments manufactured from Steel Cores are a Lifetime Investment

- Fully Rebuildable

- Steel Core Resistant to Cracking or Breaking

- RPM Engineered Wear Profile Based off 30+ Years of

recorded inspections - RPM Engineered Premium Chrome Carbide Overlay

- Steel Segment Profile Machined for proper fitment and minimizing damage on table ring

- Laser Scanning of Mill ensures exact fitment of segments

Contact Us

Have a Question?

Mailing Address

RPM & Associates, Inc.

333 Concourse Drive

Rapid City, SD 57703